In this study, we’ll be going through the various uses of horizontal formwork, slabs and their types.

Slab and formwork

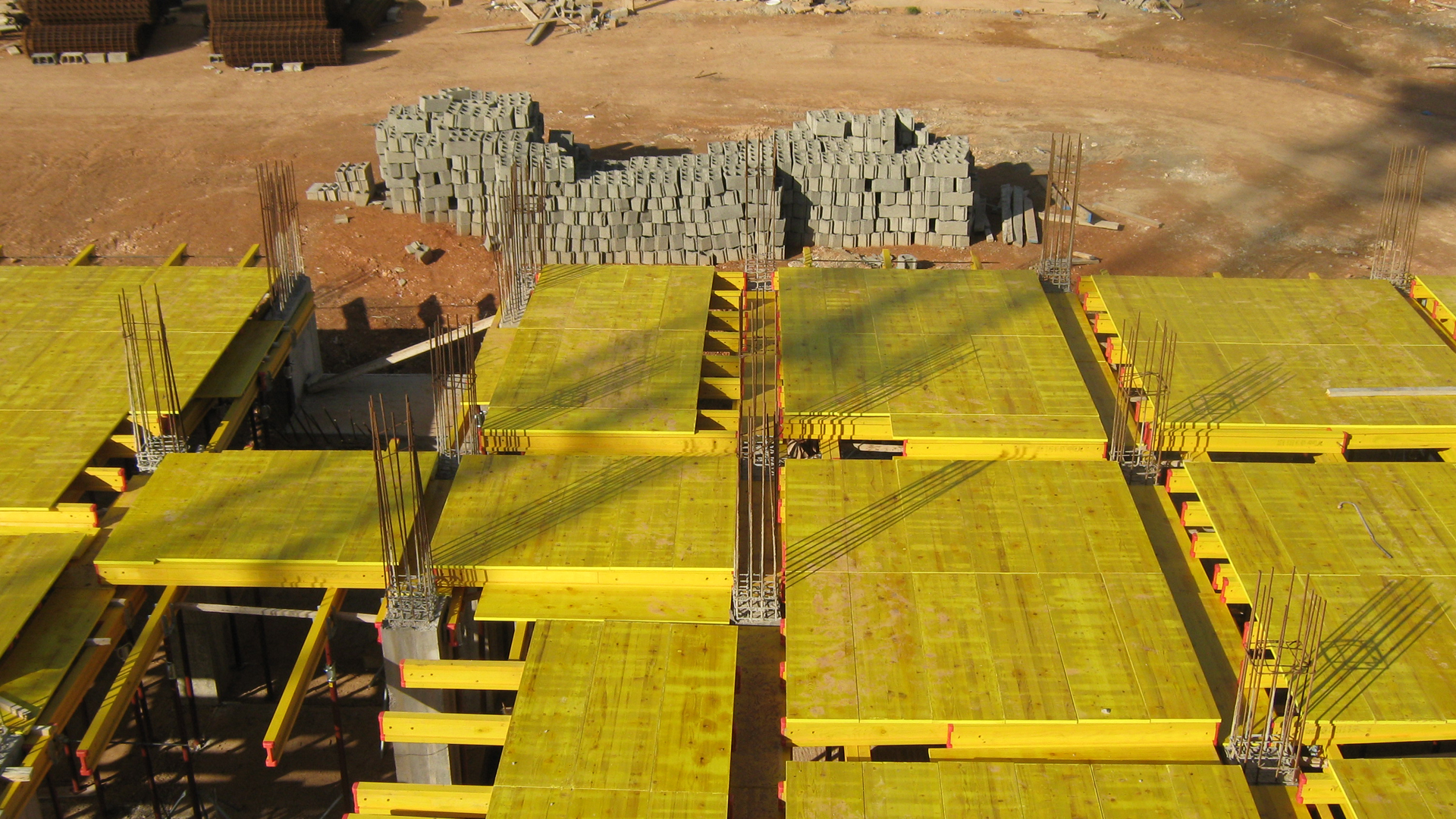

The concrete slab is two-dimensional common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete. It supports the floor by distributing the loads over the beams of the building structure. To do so, horizontal formwork systems are designed and put in place to support reinforced concrete prior to its hardening (mechanical properties).

Before walls, columns and slabs of reinforced concrete may literally hold live loads, the formwork systems (panels) play the role of “supporting” the material during setting and hardening. The setting usually lasts 24 hours and lets the material to acquire only a solid consistency. Whereas the hardening is the process that leads the concrete to gain its mechanical properties in about 28 days.

Slabs can be divided into the following categories:

– Self-supporting slab

– Waffle slab

– Cooperating

– Non-cooperating.

Self-supporting slab

All loads on this type of slab are distributed directly over the load-bearing structure and cover the entire span of a mesh without cross beams.

There are two different construction methods they are made by:

- Using prefabricated elements

- flat plate

- ribbed

- wood plank

- Cast in situ

- full slab

- ribbed slab

- ribbed slab with continuous and flat intrados

Waffle slab

On these slabs, the loads are distributed indirectly over the bearing structure by uni- or bidirectional linear elements, which support the elements of the deck.

According to the resistance of the slab as a whole, the warp and the deck can be collaboratingor non-collaborating.

Collaboratingwhen they participate in the flexural strength of the slab along with the warp and deform likewise.

Non-collaborating when they do not participate in the flexural strength of the slab with the warp.

Slab formwork systems

Whatever the slab type a formwork system is mandatory and necessary in order to support such a significant amount of weight; hence it has to be sturdy, resistant and feature a high opposition to abrasion and atmospheric agents.

They are generally lightweight and easy to handle for a quick and simple use.

In particular, horizontal formwork systems are made of three main elements:

- formwork surface (panel) which provides consistency and allows the distribution of loads;

- a horizontal structure formed by beams and joists that distribute the loads of the formwork surface over the vertical structure;

- a vertical structure, composed of uprights, which distribute loads to the lower floors or the ground.

Slab formwork systems may vary in type. Aluminium-framed modular panels with a phenolic plywood, aluminium beams and props. Sometimes the multilayer panel can be aluminium-framed birch. Else, they can be traditionally mounted using carpentry with joists and pinies.

Below are the photos of some CONDOR-branded horizontal formwork systems.

Slab formwork system: Aludeck formwork

Slab formwork system: Aluplus formwork

Slab formwork system: Multiportal formwork

Slab formwork system: ECO formwork